Three Platowood products can now be found with category 1 dates in the National Environmental Database

Interview with general manager Bart Raymann

In 1972, in the middle of the oil crisis, a way to make wood rot-resistant is discovered by chance. That year, Shell Research conducts research into extracting oil from wood. The research fails, however, and Shell quits. Researcher Herman Ruyter does discover something else. In 1989, he describes the hydrothermal modification process of wood for the first time in a scientific publication. It is the start of the company Platowood. From a startup of inventors and lab technicians, Platowood transforms over the past decades into an international producer of sustainable and platonized wood for architects and other specifiers. Three products can now be found with Category 1 data in the National Environmental Database.

The name Platowood comes from the code name of the research behind the company: PLATO, an abbreviation for Providing Lasting Advanced Timber Option. Now the hydro-thermal modification process that makes wood rot-resistant is called “platonizing. General manager Bart Raymann tells us what this means.

"Other processes in which wood is treated often consist only of drying and heating, sometimes to 200 to 230 degrees. In platonizing, we boil, dry and bake the wood. This is done at relatively low temperatures. As a result, the wood retains its cell structure and new stable compounds are created. The extra process step compared to thermal modification makes our wood stronger and more resilient. The wood absorbs less moisture, reducing shrinkage and swelling. It also prevents later fungal growth because sugars are broken down. Without using chemical additives, we can thus enhance the good properties of wood and the wood can continue to be used outdoors untreated."

General manager Platowood

Bart Raymann

Transformation process

Platowood uses fast-growing wood from sustainably managed forests. Such as Fraké, a fast-growing hardwood species from West Africa. "This wood was previously not harvested at all because it rotted quickly. With our process, we transform it into a usable material. In the forests where it comes from, only three or four trees are taken out per hectare, no more. Then that spot is left alone again for 30 years. In the time that the wood hangs on the facade, new trees grow again. That happens automatically in the jungle, you don't have to plant those trees."

Better than CO2 neutral

Platowood is actively working on its carbon footprint. "We have no gas connection on our premises.We only use steam for our production process, which we get supplied from the power plant around the corner.And with more than 3,000 solar panels, we provide our own electricity.This makes us more than CO2 neutral.Our wood stores more CO2 than we emit."

Continuous research

"Our credo is smart, inspired and tough.From these values, we devise new, innovative applications and continually search for opportunities to become more sustainable. In the fire retardant world, for example, a lot is happening at the moment. After a long search, we managed to find a biological fire retardant that does not contain any harmful substances. We now have our wood treated with that."

"We also work with a biological, waterproof glue and are now in a research process with the manufacturer of this glue to see if you can reclaim this glue back to its original raw material. We have an autoclave (ed. steam sterilizer) here for that purpose. Innovating for more sustainability is really in our DNA and we do as much as possible in-house. In our production plant in Arnhem."

Insight through LCAs

To gain even better insight into opportunities for further sustainability, Platowood commissioned life cycle assessments of three products from three wood species: from Spruce, Poplar and Fraké.

"What surprised us in that LCA is that the impact of shipping the wood from Africa is relatively small. It confirmed for us that the forests are indeed managed very sustainably.They have done an excellent job there.All the wood we buy must also meet all kinds of labels, otherwise we don't buy it."

Making transport more sustainable

"What we learned is how much you factor in internal and external transportation.We already drove electric ourselves and accelerated the switch to electric forklifts. For the external transport, we are going around the table with our partners and we are looking at whether we can keep more in-house."

"We have grown significantly in recent years.This forced us to outsource planing and profiling work from rough planks to façade profiles.As a result, there are trucks driving up and down.Therefore, we are now expanding our production site so that we can do this ourselves again.Last year we acquired a new planer, among other things.And so we are constantly pushing to do more processes ourselves. These are huge investments and they are worth it. We then have the direct influence ourselves to make those processes as sustainable as possible."

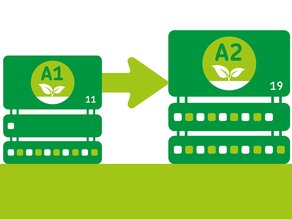

With category 1 data in the NMD

With the LCAs under our belt, the step to inclusion in the National Environmental Database was a small one. "We hope this will make it even easier for architects to find us and prescribe more easily.Another nice thing is that it is now public, substantiated and clear what we do.The Environmental Cost Indicator (EQI), which summarizes all environmental effects in a single score in euros, makes your products easily comparable with others.We have now started with three products, but more are sure to follow."

Intrinsic motivation

Bart thinks it's a great development that sustainability has become a prerequisite in construction."I do think that the intention of sustainability is now still very much under a magnifying glass.You have to document and certify all kinds of things to prove that you are sustainable. But shouldn't that just be in the DNA?We think in terms of sustainability.Making the world more beautiful together.That drive to do the right thing well is very strong.I hope that in more and more companies that intrinsic motivation will prevail."

Proven sustainable

Having a life cycle analysis done and having your products with category 1 data included in the NMD is something Bart recommends to everyone. "It gives you a lot of insight into your company and your products.Moreover, you make visible to others how you score.I expect that you will soon be out of the running if you cannot show very clearly and substantiated how sustainable your products are."