Featured category 1 environmental declaration

CMPC with category 1 data in the Dutch Environmental Database: “Clear and independent benchmarks are crucial”

CMPC is one of the largest forestry and paper companies in Latin America. The company produces pulp, paper and wood products, including structural plywood. In the Netherlands, CMPC is represented by Koninklijke Eduard van Leer (KEVL). In that role, Goderd Hooft Graafland and Sander Daatselaar are driving forces behind the inclusion of CMPC’s products in the Dutch Environmental Database. “Convincing a multinational to invest time, money and attention in a country-specific system like this takes some persuasion – but CMPC definitely sees its value now.”

CMPC manages more than 1 million hectares of forest plantations, primarily in Chile, Argentina and Brazil. Around 550,000 hectares of this area consists of plantations of Radiata Pine and Eucalyptus. The rest is managed as nature reserves or buffer zones.

Within the Dutch construction sector, CMPC is mainly known for its structural plywood panels. These include the CMPC SELEX® Radiata Pine plywood panels for floors and roofs (18 mm, 15 mm and 12 mm), which are now included in the Dutch Environmental Database with category 1 data.

Goderd Hooft Graafland and Sander Daatselaar explain in this interview why inclusion in the Dutch Environmental Database is so important for CMPC – and how they managed to convince the multinational to invest in such a country-specific system.

A frontrunner in sustainability

Goderd: “CMPC has a strong intrinsic motivation to further expand its sustainability efforts. It ranks among the top companies in the Dow Jones Sustainability Index and was named the world’s most sustainable company in the ‘Paper & Forest Products’ category in both 2023 and 2024.”

“CMPC has also been FSC-certified for sustainable forest management for many years and was one of the first panel product manufacturers to publish a Life Cycle Assessment (LCA) and Environmental Product Declaration (EPD).”

Creating impact

Sander: “It’s also impressive to actually visit their operations in Chile. The headquarters is located in Santiago, where CMPC was founded in 1920. The company has grown immensely – its forests stretch all the way to the Andes. CMPC consistently invests in innovation and sustainability.”

“One concrete example: climate change, which among other things is leading to longer periods of drought and water shortages, is a growing issue worldwide and particularly in South America. CMPC has been working for years on developing improved seeds. The aim: to grow trees that are more drought-resistant and require less water. With operations of this scale, CMPC can really make a significant impact.”

Fully integrated operations

Goderd and Sander have also noticed that timber construction is gaining traction in the Netherlands as interest in biobased building materials increases. “Trees absorb CO₂ as they grow. So when you build with wood, you effectively store CO₂ in the building. What makes CMPC unique is that it controls the entire value chain – including its own plantations. CMPC owns one million hectares of forest, runs its own nursery for ongoing research, and operates a modern factory where the plywood is manufactured.”

Transparency in sustainability

Sander and Goderd have seen a growing demand in recent years for factual insights into the sustainability of CMPC’s products. “Clients, architects, structural engineers and builders increasingly want to understand how products compare in terms of sustainability, so they can make informed decisions.”

“CMPC holds many international certifications. As mentioned earlier, it is included in the Dow Jones Sustainability Index and holds FSC certification. But for the Dutch market, inclusion in the Dutch Environmental Database is essential, that’s the go-to source for architects and builders to compare materials.”

From category 3 to category 1

“There has been a lot of recent movement in the Dutch timber sector. Centrum Hout, together with parties such as TBI Woonlab, TU Delft and Lister Buildings, contributed dozens of new and updated environmental declarations for timber products to the Dutch Environmental Database, under the FSC® Netherlands-initiated project Home for the Future. That was an important step, since timber construction products had long been underrepresented in the database.”

“Making category 1 data available instead of category 3 data is crucial to capitalise on the positive impact of timber products in environmental performance calculations for new-build projects. That’s exactly the conversation we’ve had with CMPC.”

Additional data required

“That wasn’t easy at first. Even though sustainability is a core priority for CMPC and they’ve been publishing LCAs and EPDs for years, the Dutch system requires additional data. We work with different and more categories here. It’s quite a challenge to explain that to a foreign company – especially when a previously verified EPD needs to be reassessed.”

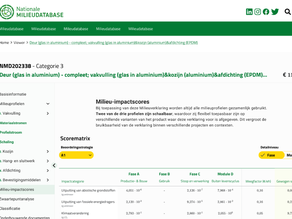

New insights with the ECI

“Thanks to a business case analysis, we were able to convince CMPC to invest in additional data for what is, in relative terms, a small market. The result? The Environmental Cost Indicator (ECI) has proven to be a real eye-opener for CMPC. Never before had the company seen its environmental impact expressed in such concrete cost terms. It makes the financial value of CMPC’s sustainability investments suddenly very tangible and clear.”

More focus on scope 3 emissions

“What’s more, the questions we asked in order to produce this Dutch environmental declaration also helped sharpen CMPC’s internal processes. It raised awareness even further – especially in terms of making existing LCAs truly accessible for our clients.”

“In addition to all the sustainability initiatives already mentioned, CMPC has for years been researching how to make its adhesives more environmentally friendly, reduce plastic in packaging and decrease reliance on fossil fuels. The company has set concrete goals for this. For example, aiming for zero waste and a 25% reduction in industrial water consumption per tonne of product by 2025. And reducing direct and indirect greenhouse gas emissions by 50% by 2030.”

Continuous improvement

“90% of the energy used by CMPC already comes from renewable sources. Now, there is also increased focus on scope 3 emissions – the emissions not directly caused by CMPC itself, but occurring in the value chain, all the way to end-of-life. It’s great to see how CMPC continues to raise the bar. And it’s a good thing that the SELEX® products are now listed in the Dutch Environmental Database. To further improve sustainability in the sector, clear and independent benchmarks like the Dutch Environmental Database are essential.”

This article was published on 1 August 2025

Read more