‘Biobased housing "behaves" differently from traditional construction’

Architect and client collaborated on a pilot project

Biobased construction is considered an interesting development at Buro de Ville in Loon op Zand (North Brabant). So when someone approached them with the wish to build a biobased villa, architect and co-owner Boyke Kooijmans saw it as an attractive pilot project. “Biobased construction is a very pure way of building.”

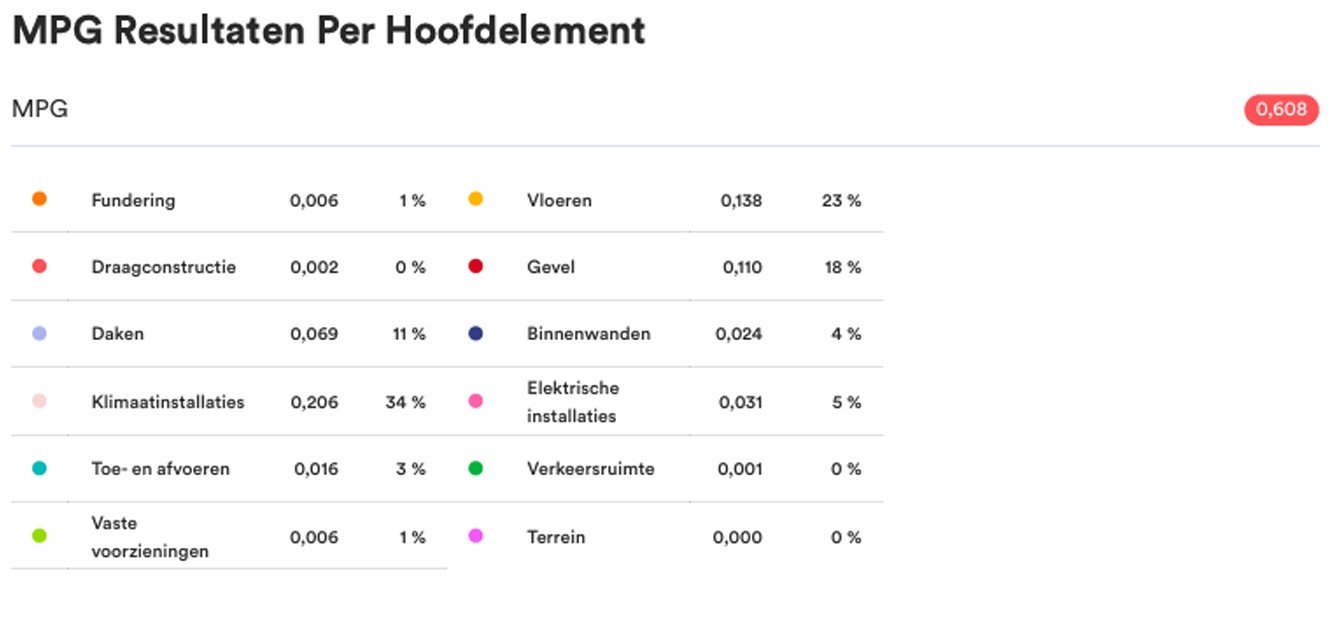

The architect designed a detached house for an elderly couple, commissioned by their son. The couple has been living there since the summer of 2025. Their life-course-proof home contains many biobased materials and has a solid MPG score of 0.6.

Keep thinking and stay open to other techniques and materials

This firm consists of three architects, three structural engineers and an office manager. The client for this project is Victor Kooijmans, a second cousin of Boyke. The architect learned a great deal from the process and shares his key lessons. “Even if you think you know how to approach certain things, keep thinking and stay open to new products that may require a different way of designing and building.”

His practice already had extensive experience with timber frame construction, which formed the basis of this project. “The pilot worked out well. It was challenging to step away from what I was used to and to explore new building methods. Victor is a great client; he is open to everything, always asks follow-up questions, and was willing to choose biobased solutions even though it cost around 15 percent extra.”

What does this architect see as the biggest difference between traditional and biobased construction? “Traditional materials require a lot of energy.

This biobased home is an interplay of renewable resources — a kind of building kit that behaves very differently. For example, it contains more timber connections, because we wanted to use as little concrete, masonry and steel as possible. The floor, façade and roof are therefore composed and connected differently than in traditional construction.”

‘I had no idea what biobased actually means’

Client Victor is an entrepreneur. He runs a company that supplies stages for festivals and events. In addition, together with his wife, he is the initiator and owner of two floating hotel rooms and the Bossche Kraan, a former loading and unloading crane at the Tramkade in ’s-Hertogenbosch. He also developed this project together with Boyke; the Bossche Kraan has since been converted into a hotel room.

Victor lives with his family in a detached house in Vught. “My parents are both well into their eighties. They lived in a rural area on a large plot of land and regularly need assistance. Finding a life-course-proof home in Vught was not possible, and certainly not one with some space around it.” Victor decided to investigate whether he could build a house on his own property, on the site where an old barn once stood.

His wish list? No thresholds, all facilities plus a bedroom and bathroom on the ground floor, and sufficient space in corridors and rooms to accommodate wheelchair use. Victor: “And it was a strong wish to build a biobased home. But I had no idea what sustainable and biobased construction actually entails, which materials are available, or whether it is affordable.”

Future-proof

The barn already had a residential designation, and the municipality agreed to demolition and new construction. Boyke and Victor then worked together on the design. Boyke: “The first challenge was to design the detached house within the footprint of the barn, as this was a requirement set by the municipality. We wanted to make the house future-proof and therefore also suitable for future occupants who may want to sleep upstairs.”

They therefore opted for a slightly taller building with dormers and, on the upper floor, three full-sized bedrooms and a bathroom. Boyke: “The house offers Victor a future perspective that aligns with his investment.”

Flax insulation and biobased window membrane around the frames

Victor was a highly involved client. He not only helped with the construction himself (more on that later), but also immersed himself fully in the world of biobased materials. Through an entrepreneur who runs a wholesaler of (green) building materials, he received many tips. Thanks to this specialist and his own research, Victor discovered a wide range of biobased materials. “I learned, for example, that you can insulate with hemp and flax. That was exactly what I wanted for the house for my parents. Step by step, I became increasingly enthusiastic about biobased construction.”

Boyke: “The roof is insulated with Isovlas insulation boards. This is a cradle-to-cradle product. It provides insulation, sound absorption and moisture regulation. Isovlas has a category 1 environmental declaration in the Dutch Environmental Database.” On top of the Isovlas insulation layer, steel sheeting is used as roof covering. Boyke: “Not ecologically ideal, but it has a very long lifespan and steel is 100 percent recyclable. And we really like its appearance. It allows for very clean detailing, as no overhanging gutters are required.”

Another noteworthy product is the biobased window membrane from Pro Clima, which was recommended to Victor. “It makes window frames airtight. There is a 50-year guarantee on this product, which I think is ideal.”

Victor actively participated in the construction process, partly because he enjoys it and partly to reduce costs. “I helped almost every day. I worked closely with a carpenter, an electrician and a plumber, and I handled the site supervision.”

Practical considerations in material choices

The architect and his client did not aim to be pioneers in every aspect. Boyke: “Several factors played a role in the selection of materials: the level of sustainability, the price, and also practical considerations.” For example, the ground floor slab is made of concrete. Boyke: “This floor contains steel reinforcement, and we used several steel portal frames (two columns plus a beam) to span larger distances. Yes, we could have opted for double-laminated timber beams, but then the dimensions would have become too substantial.”

The insulation beneath the floor is not biobased. Victor: “In 1998, I renovated a small farmhouse. At the time, I chose a biobased product for floor insulation, but its thermal resistance value was far too low. For this house for my parents as well, I opted for traditional insulation beneath the floor.”

The glazing in the window frames is double HR++. Boyke: “The frames are made of wood, so HR+++ would have been possible, but that would have made the façades extremely heavy. And new HR++ glazing is simply more cost-effective, while still offering a high level of insulation.”

Hemp fibre board has a positive effect on the MPG score

The limited use of concrete and steel, combined with the large share of timber and other biobased materials, results in the solid MPG score of 0.6. The structure does not consist of wood alone; the façade is clad with fraké wood, a fast-growing timber species. Boyke: “The black colour was achieved in a sustainable way through thermal modification.”

Victor also chose hemp fibre board as an additional layer of façade insulation. “This material was recommended by the contact from the building materials wholesaler. He advised us to opt for a vapour-open façade and warned that applying insulation foil directly onto the timber frame would create a thermal bridge. He recommended cladding the timber structure with hemp fibre board, as it is not only biobased but also water-resistant and vapour-open.”

Boyke: “I had the effect of the hemp fibre board calculated. This material has a positive effect on the thermal resistance value. We could also have chosen to insulate on the timber frame and add an extra shell around it to prevent thermal bridging, but that would require additional material, and that choice would have increased the MPG score.”

Happy with the choice for sustainable geothermal energy

And how do the residents feel about their special home? Victor: “They are very happy living there. Their previous house had a beautiful historic façade, but it was uninsulated. In winter, they were always cold. They are now especially pleased with the pleasant indoor temperature.” This comfortable indoor climate is the result of a ground-source heat pump combined with underfloor heating and marmoleum floor finishes. Victor: “My parents also really appreciated the cooling via the floor during last summer.”

Boyke: “Yes, in that respect this system truly differs from an air-source heat pump. With geothermal energy, you can cool passively.” Victor chose geothermal energy not only for sustainability reasons, but also because of noise — or rather, the lack of it. “Many people I know find that outdoor units produce a lot of noise. Some even lie awake at night because of the humming.” He accepted the higher investment. “I chose to make that extra investment because I ultimately want to build a fully biobased home. I found it enjoyable and interesting to go as far as possible with this house. So yes, I could have built it more cheaply, but I really like having this geothermal heat pump now and experiencing how sustainable and quiet it is.”

Detached, biobased and life-course-proof home in Vught

Victor Kooijmans had a home built on his own property for his parents.

Project highlights:

- Vapour-open and biobased

- Timber frame construction using spruce wood; extends CO₂ storage

- Complies with BENG requirements

- Façades, walls and intermediate floor are also made of timber, resulting in low greenhouse gas emissions

- Natural insulation materials with moisture-regulating properties

- Ground-source heat pump using geothermal energy

- Eight solar panels on the front-facing roof

- Rainwater retention on site through infiltration and a sedum roof on the flat roof sections. The sedum roof provides additional cooling in summer and extra insulation in winter, increases CO₂ uptake, enhances biodiversity and extends the lifespan of the roof covering

They jointly realised the biobased villa in Vught:

Client: Victor Kooijmans

Architect: Buro de Ville – Boyke Kooijmans