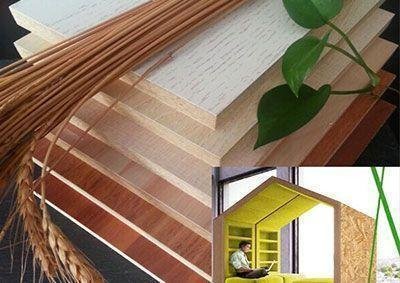

Biobased sheet material from ECOBoard International with CAT 1 environmental statement in NMD

ECOBoard International's biobased board materials are listed with category 1 environmental data in the NMD.

ECOBoard International's biobased sheet materials are listed with Category 1 environmental data in the National Environmental Database. ECOBoard's board material is made from waste materials derived from agriculture. 100% of the board consists of straw (wheat) and (residual) wood (poplar), which is bonded with over 95% natural lignin, a 5% non-toxic binder without formaldehyde (NAF). This makes the board material almost entirely biobased and completely circular. We spoke with founder of ECOBoard International Waldo Chotkoe and his business partner Joost Karsten.

Waldo stumbled across the sheet material made from rapidly regrowable raw materials in China about 15 years ago. Clever, he thought. “Wood, of course, is also a biobased product, but trees grow quite slowly. If you cut down trees to make wood for construction, it can take decades for such a forest to return to the same size and take the same amount of CO2 out of the air as before. A raw material for this panel material, such as wheat straw, stores CO2 faster as it grows. It is a fast-growing annual crop. So very quickly regrowable. Moreover, this product is made from residues. My then partner and I thought: we have to bring this to Europe.”

Waldo Chotkoe en Joost Karsten

ECOBoard International

To the European market

Waldo and his associate delved into the manufacturing process and applications of the material to EU standards with Chinese people.

“We saw that in China and the EU it is used in a variety of ways in interior construction. As an alternative to MDF and OSB boards in the construction of buildings, but also, for example, in the manufacture of furniture. We started looking into the product and developing it further to make it suitable for standards in the European market.”

“In 2017, we reached that point. From then on, our products have the CE mark from Germany (in accordance with CPR harmonized standard EN 15804+A2:2019). In 2016, our ECOBoard panels were also the first biobased panel to be labeled the best DUBO choice by NIBE Research. This means that this material is labeled as the most environmentally friendly choice of panel material in the Netherlands.”

Life Cycle Analysis

Still, Waldo noticed that the parties applying ECO Boards wanted to know more about the product. They increasingly asked for a life cycle analysis. “Especially in the Netherlands, that call for an LCA was strong. We are happy to meet that demand and had that LCA made in 2023. Such an LCA tells more than the certificates we already had. And with the data from the LCA/EDP in our pocket, the step towards inclusion in the National Environmental Database with category 1 data is of course easily made.”

Negative carbon footprint

“The life cycle analysis shows that when produced locally, ECOBoards have a negative carbon footprint of -0.618 CO2 emissions per kilogram,” says Joost. “As already told, ECOBoard's board material consists 100% of agricultural residues, especially wheat straw. Fast-growing crops store CO2 in the stems as they grow, which is thus also stored in the board. Thus, an ECOBoard plate of 122cm x 244cm x 18mm can reduce the emission of 150 kilograms of CO2.”

“What's extra nice is that the residues that ECOBoards are made from are often otherwise burned. So we are using something that would otherwise not get a use. The material is bonded with a toxic-free binder (NAF) without formaldehyde, making the boards end-of-life 100% recyclable.”

Completely circular

There are more product features that provide benefits, Waldo explains. “Our boards are up to three times more resistant to moisture than traditional wood board material. After a two-hour exposure to water, ECOBoards show only 3-4% swelling and retain their screw strength and structural integrity. This makes ECOBoards very suitable for application in kitchens and other damp areas, for example. Our boards are also very smooth for a beautiful finish and have an estimated lifespan of 75 years, after which the material can be reused again and again.”

Transparency through data

Joost: “What we now see in the Netherlands is that interest in bio-based building materials is growing. However, there is also still reluctance. Biobased materials are often not yet mass-produced. Architects and builders wonder whether these materials offer the stability and reliability you need when building or renovating a house or building.”

“We hope the certificates and data from our ECOBoards will dispel that doubt. China produces 500,000 m3 of ECOBoard annually. The board material has been widely used in interior construction there for more than 15 years. A tremendous amount of innovation has been done and all risks have been eliminated. It is a stable product that has proven itself in practice.”

“We have also become a core partner in the international ALOHANA network. Within ALOHANA, ECOBoard is processed in the manufacturing industry in various applications for interior construction, allowing us to offer ready-to-use processed solutions, such as frames, doors and complete interiors.”

Continuous further sustainability

ECOBoard International also has ambitions, as the company scores the lowest on logistics. Waldo: “In the Netherlands there is now a lot of focus on bio-based building materials made from locally grown raw materials. I understand that, but I also find it an interesting discussion to what extent that is realistic. Do we have enough room for that in the long run, as the share of biobased building materials grows? Besides, it is not there yet on a large scale, while we in the Netherlands do want and have to make that step towards biobased. Wouldn't it be better to choose what is already there?”

Joost: “Now our materials still come from far away, but we have plans to make the whole process more regional. We are also making the logistics chain more sustainable in other ways. In Portugal, for example, we are already making total concepts from our sheet material in combination with other sustainable brands. So we don't sell individual sheets, but complete products. That factory in Portugal runs on hydropower and logistics as much as possible on biogas (LNG) from our own production process. We are very conscious of that.”

Building to 2050 standards

Waldo: “The score we are getting now is not yet fully representative of all the developments going on. Who knows what is still to come in that area. But we do make building according to the standards of 2050 already possible now and hope that the inclusion of our products in the National Environmental Database will make that clear to everyone in the industry.”

This page was translated using DeepL.