Berkvens Deursystemen: “Environmental data provide valuable insights for better decisions”

Sustainability has been an integral part of product development at family-owned Berkvens Deursystemen for many years. According to Pieter Fritz, sustainability manager at Berkvens, it is “just using common sense” to make the best products. Life cycle analyses (LCAs) play a central role in this process. These analyses provide insight into opportunities for further sustainability. And with this insight in hand, the step to inclusion in the National Environmental Database is quickly made. “Our goal is to have more than 70% of our product portfolio in the NMD by next year.”

Berkvens is a company with more than 90 years of experience, where the fourth generation of the family is now actively involved in the business. With almost 500 employees on board, some million doors and frames, mainly for residential construction, are produced annually. The role of doors has changed greatly over the years: from functional objects, doors have evolved into an integral part of interior design, in which aesthetics, acoustic properties, fire resistance and even bullet resistance have become increasingly important.

Berkvens Door Systems

Pieter Fritz

Innovation and sustainable customization

It is one of the aspects Berkvens is constantly innovating on, Pieter explains. “Besides functionality, aesthetics also play a role nowadays. As a result, you get a different composition of the product. With more glass, line recesses and also floor-to-ceiling door models. We have adapted our production process to this so that 'mass customization' is possible. This way, we can continue to produce smartly while providing customization.”

Social responsibility

Sustainability has always been a core value in Berkvens' design and development process. “For a long time it was not a specific spearhead, but just something you do as a family business,” says Pieter. “As part of your responsibility to future generations and because you simply want to deliver a good product. For example, we were the first interior door manufacturer to start working with FSC wood to save tropical forests. Later this developed further into other materials with even less environmental impact.”

Concrete sustainability policy

When Berkvens decided around 2018 that sustainability needed to become an integral part of the organization and business operations, a position was vacated that Pieter still holds to this day. “A strategy and policy was developed to become more sustainable throughout the chain. Clear goals were attached to this, such as the use of 50% recycled or bio-based materials and a 50% CO2 reduction in the entire value chain towards 2030.

Substantiated insight with LCAs

LCAs help Berkvens make targeted improvements. For example, they show that the greatest environmental impact of doors does not come from paint or glue, but from cover boards, chipboards and MDF. This insight led to more focused internal improvement processes.

“For example, we are investigating the impact of a greater focus on renewable materials, what alternatives are available for the additives needed for fire resistance, and what environmental impact we can achieve by changing our packaging methods.”

The power of numbers

“A great example of the power of numbers is our use of materials. Originally, we always packaged our doors in plastic, but for sustainability reasons we wanted to switch to cardboard. However, to transport doors safely, so much cardboard would be needed that using it would result in more CO2 emissions than plastic.”

“We therefore continue to use plastic, but have converted it to mono-flow so that it can be guaranteed to be recycled. All parts of our packaging, such as stickers and printing, are now made of the same type of plastic. We also focus on minimizing packaging and use recycled materials as much as possible. When we purchased our new packaging machine, these were also partly the requirements, so our packaging process has been adjusted accordingly.”

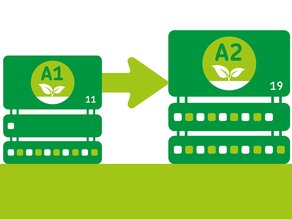

With CAT 1 data in the NMD

For Berkvens, LCAs were never intended as a means of showing how well products score on sustainability. However, the demand for concrete data from the market increased, which led to an increasing number of Berkvens products with category 1 data being included in the National Environmental Database.

“We think it is important that this happens industry-wide. First of all, insight into environmental data can help enormously in making the right choices. The path to sustainability is sometimes different than you might expect, and data gives you concrete guidance for that.”

“Second, category 1 data provide the most accurate calculations toward an MPG (Environmental Performance of Buildings). If we collectively in the industry want to take steps toward a more sustainable construction sector, it is essential to do this as transparently and comparably as possible.”

“This is why we are not limiting ourselves to one or two sustainable products, but are including our entire product range. Next year we want to have more than 70% of our products in the National Environmental Database, which amounts to about 100 product cards. It would be very nice if everyone would do that.”

Nieuws